What you will learn in this ebook?

Contrast and understand the subtle but transformative difference that greyscale brings to more traditional photo lithography.

The greyscale method is difficult to accomplish due to the many steps involved and the non-linearities at every stage. Gain a good overview of six key variables necessary to optimize the flow.

Learn about the amazing array of device structures that can be created using the power of greyscale thus opening up many new applications.

What is Greyscale Lithography?

Greyscale lithography is variant of photo lithography called greyscale (or grayscale), now commercially available, opening up entirely new possibilities for the types of structures that can be fabricated. This disruptive technique is starting to take hold in the industry and is enabling both new MEMS applications as well as improving current ones.

More specifically, it is a method for shaping resist in the Z dimension using semiconductor wafer processing. Devices interacting with the waves or fluids at the microscale can more optimally function with smooth, tapered, or rounded curves in multiple axes. While traditional semiconductor photolithography has advanced to include curves in the mask layer that result in rounded structures, they are limited to the x and y dimensions. Greyscale lithography addresses the z dimension.

Learn about the six variables tackled over the past two decades when optimizing flow.

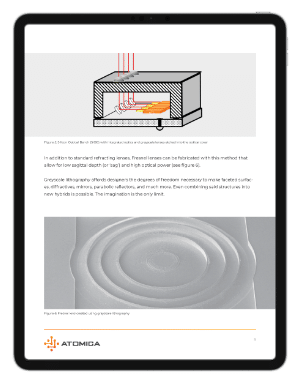

01. Exposure Method

Direct write methods using e-beam, laser writing or DMD are common but slow. It is also possible to use a reticle or mask, but the design is more challenging.

02. Exposure Conditions

Significant process development goes into finding just the right energy, focus and other parameters.

03. Design

Mask editing software frequently limits the designer to geometric shapes, but plug-ins and homebrew software enable a mask designer to properly control the exposure.

04. Photoresist choice and preparation

The properties of the resist and the method with which it is coated on a wafer play a significant role in the quality of the greyscale pattern and etch.

05. Etch recipe

A critical step in the process involves the complex recipes that address the peculiarities of etch rate of resist versus the substrate.

06. Process control

Greyscale lithography is particularly susceptible to process variability, and requires a fab with excellent process control.

GREYSCALE LITHOGRAPHIC APPLICATIONS

01

Lenses and Optics

There are many infrared applications for exotic lens materials shaped via greyscale methods, including thermal imaging, night vision, LiDAR, many bands of telecommunications, and many types of spectroscopy.

02

Kinematics

There are many optical benefits of grayscale lithography involving the mechanical advantages gained from gradient masks and etching to create various kinematic surfaces for mounting active and passive optical components.

03

Microfluidics

Lab-on-a-chip devices typically comprise a collection of wells, channels, mixers, pumps, valves, manifolds, and/or chambers that perform sensing or biological functions. Grayscale lithography techniques enable these biochip features to be created in glass or silicon.

04

Sensors and Actuators

Designs that can leverage the mechanical benefits of curves are limitless; sensor and actuator applications are quickly expanding due to grayscale technique advances.