Exceeding Expectations:

Delivering Superior Quality in Microfluidic Chip Fabrication

Unlock the power of Atomica’s Microfluidic Platforms. Our expert team is dedicated to turning your microfluidic chip design into a functional reality with our cutting-edge fabrication processes.

Microfluidic biochips are at the forefront of miniaturized analysis systems, blending biology and engineering.

These compact tools facilitate precise control of tiny fluid volumes, allowing unprecedented manipulation of biochemical conditions. With superior sensitivity and specificity, they’re invaluable in fields like clinical diagnostics and environmental monitoring. Harnessing technologies like microarrays and lab-on-a-chip systems, microfluidic biochips are ushering us into a new era of precision and miniaturization.

Atomica’s Comprehensive Microfluidic Solutions

Microfluidic Actuators

At Atomica, we leverage our decades of MEMS experience to fabricate micron-scale actuators that enable precise movement of small liquid quantities. Our sophisticated processes span various substrates, including gold, platinum, and magnetic permalloy, delivering high-performance actuators for microfluidic applications.

Micropumps

Atomica’s expertise in magnetic actuation and materials like silicon enables the development of advanced micropumps. From passive capillary flow to precise aliquot volumes and optimized flow rates, our micropumps deliver functionality and reliability for your innovation needs.

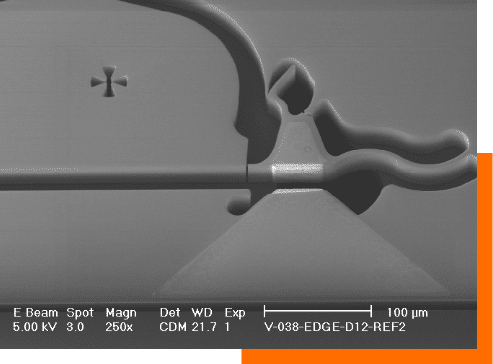

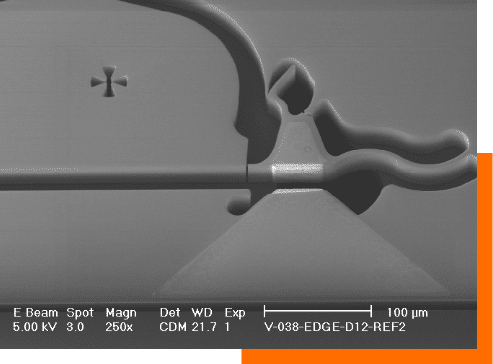

Microvalves

Regulating fluid movement, microvalves are crucial in microfluidic systems. Atomica’s microvalves utilize thermal, chemical, electrochemical, magnetic, or electrostatic actuation. Our collaboration with Miltenyi Biotech resulted in the world’s fastest microvalve, employing magnetic actuation.

Microchannels

Microchannels are the pathways for fluid flow, controlled by micropumps and microvalves. In a “lab-on-a-chip” setup, microchannels serve multiple purposes, including temperature changes, aliquoting, mixing, and reagent addition, enabling efficient chip processes.

Microwells

Microwells act as reservoirs or ports for introducing external liquids and storing fluids in microfluidic systems. They play a vital role in lab-on-a-chip processes, facilitating sample handling and storage within the microfluidic topology.

Coatings

Atomica offers advanced deposition technologies for passivation, metallization, and more. Our ability to pattern metal electrodes enables on-chip functions like electromagnetic actuation, electrophoretic separations, or electrochemical detection. Our wide range of coatings and metals ensure critical properties for optimal functionality.

Microfeatures

Microfluidic devices often incorporate microfeatures like filters and micropillars. These features purify analytes, break up cell aggregates, and sort sample components based on size. Atomica utilizes advanced greyscale lithography to craft microfeatures such as micropillars for diverse applications.

Microneedles

Atomica specializes in the fabrication of microneedles for applications like drug delivery and laboratory manipulations. Our expertise in materials like silicon, metals, and polymers, along with intricate processes like wet etches and complex deep DRIE, ensures the production of strong and biocompatible microneedles.

Need any of the above solutions? Schedule a call with our technical experts to discuss your project!

Company Facilities

Atomica is the largest MEMS foundry in the US, providing close collaboration for North American customers and the assurance that intellectual property is protected and respected. The company is privately held and controlled by Cerium Technology.

- 13-acre, 130,000 ft2 manufacturing facility with the capacity to support high volume production

- 30,000 ft2 class 100 cleanroom

- Over 400 tools for both 6” and 8” wafer production

- ISO 9001 certified (since 2006)

- ISO 13485: 2018 compliance in progress (Medical Quality System Regulation)

- IATF 16949: 2016 compliance in progress

- Mature MES, document control, and phase-gate systems

- ITAR registered

- Broad materials flexibility, providing access to an extensive set of processes and materials unavailable in CMOS fabs, including noble metals, polymers, and virtually any substrate (e.g., silicon, SOI, glass, fused silica, quartz, borosilicate, piezos, and III-V).

Applications of

Microfluidic Chips

- Disease Diagnosis: With their capacity for rapid, point-of-care diagnostics, microfluidic biochips are revolutionizing healthcare by enabling prompt disease identification and management.

- Drug Discovery and Development: Microfluidic chips facilitate high-throughput screening of drug compounds and personalized medicine approaches, thereby accelerating the development of novel therapeutics.

- Genomics and Proteomics: Through high-throughput sequencing and protein-DNA interaction studies, biochips are driving advances in our understanding of genomics and proteomics.

- Cancer Research: By isolating circulating tumor cells and conducting drug screening, biochips contribute significantly to the development of personalized cancer treatments and a deeper understanding of tumor microenvironments.

- Organ-on-a-chip: Microfluidic technology’s ability to mimic human organ functionality on chips holds tremendous potential in drug testing, disease modeling, and personalized medicine, promising to speed up drug development and reduce the need for animal testing.

Transform Your Ideas into Reality:

Fabricate Your Microfluidic Chip and Lead the Way!

“Because process and design are so tightly coupled, it’s essential to be able to work hand-in-hand with your production partner. Atomica is unique in allowing such close collaboration.”

John Harley – President, Owl Biomedical,

a Miltenyi Biotec company

Talk to one of our Biochip Experts

See how Atomica can help bring your microfluidic biochip to life.