EBOOK

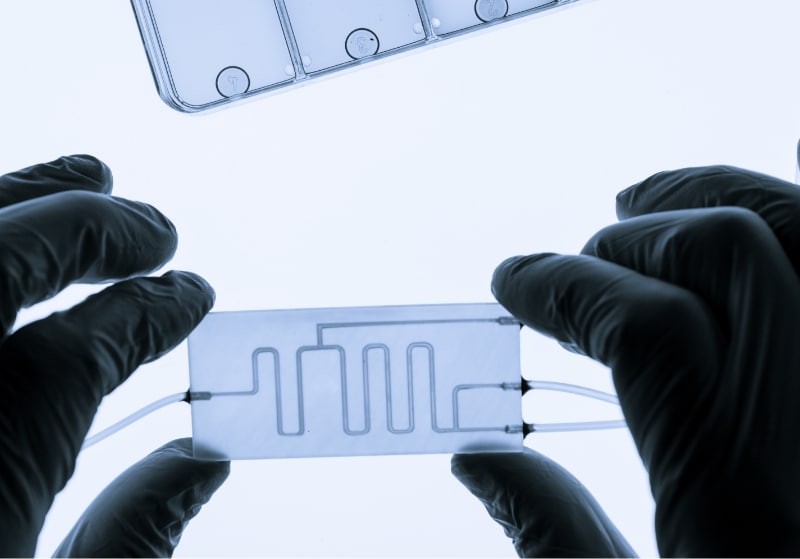

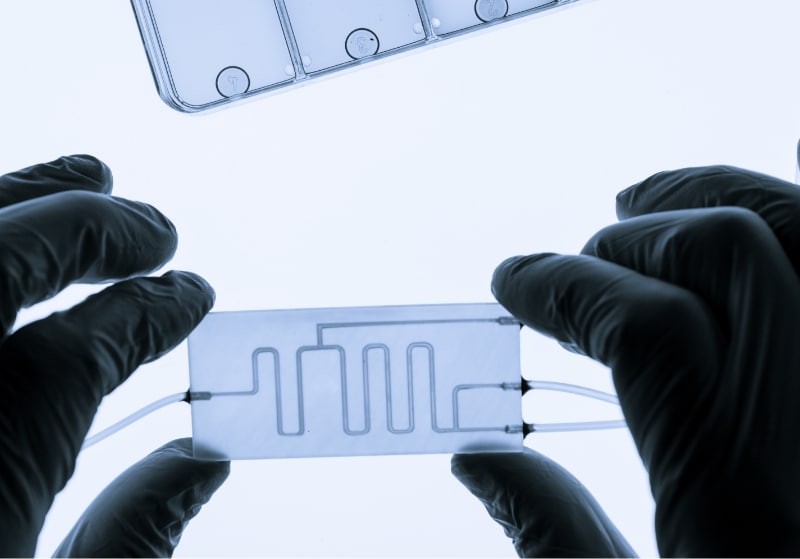

6 Critical Design Considerations for Microfluidic Biochips

Download Part 2 on microfluidics to understand the six areas that are critical in leading to scalable production of your biochip.

What you will learn in this ebook?

- Take a deep dive into the six critical design considerations that will determine the final design and production process.

- Get insight into the competencies needed in a biochip development and fabrication partner.

- Begin with a short microfluidics primer.

-

On-chip operations

As you and your team begin to conceive a microfluidic product, consider the current benchtop laboratory operations that your new product is meant to disrupt. Through research and discussion with the scientists and engineers at fabrication houses, your team will explore how your current benchtop operations can be translated into on-chip equivalents. Translation of your concept to a state-of-the-art microfluidic format begins with a block diagram of the operational flow for your procedure.

-

Design approach

After crafting a block diagram of your current benchtop procedure and brainstorming with a fabrication facility about a possible microfluidic implementation, the next step is to identify microfluidic protocols, chip designs and components that will meet your goals. While the order of operations would likely remain the same on-chip as in your benchtop approach, our team would work with you to achieve a design that emphasizes certain key aspects of the procedure that are critical to performance, reproducibility and portability, starting with operations and moving to components.

-

Materials requirements

When selecting materials for the substrates in your new microfluidics device, your team will need to view the materials requirements for a given assay or protocol from several angles. Atomica can provide our clients with a balanced view of the benefits and limitations of working with a variety of materials — whether from us or others — for a given application. Our engineers can also discuss options for hybrid-material devices, including co-manufacturing, to close technology gaps for a single material.

-

Integration

A fabrication house should be fluent in a wide variety of techniques for sample processing and analysis from the “macro world” that have been implemented in microfluidic devices. Elements of this impressive toolbox of demonstrated technologies could be integrated into your novel device.

-

Price point

Successful products sell into the target marketplace as long as they offer a compelling value proposition over competing products and approaches. For many microfluidics products, the challenge of delivering the required value in the most cost-effective product quickly raises the question of which substrates—glass, silicon, and/or plastic—and associated microfabrication processes confer the product features and hence the value that supports the desired price point, sales, and margins. Learn more.

-

Manufacturability

As for all OEM-manufactured products, Atomica’s overall goal is to support your team in designing a device that meets your goals for quality operation, manufacturing, and price point. To meet these goals, our scientists, engineers and quality-assurance personnel work with your team to discuss manufacturability considerations.